YOUR SUCCESS IS OUR SUCCESS

ABOUT US

• SONXI focuses our business on Jewelry and High technology plating.

• 2008 - Set up the first workshop 2500 feet square in Ho Chi Minh city.

• 2015 - Build new factory 32000 feet square in Binh Duong province.

• September 2019 - Starting a new R&D and Automation center in Binh Duong province.

• OEM/ODM services.

• Average 50.000 units/month.

• Focus on Brass, Stainless steel, Silver, Gold.

• 60 staff in Ho Chi Minh, 60 staff in Binh Duong.

PRODUCT

• Ring.

• Necklace.

• Chain.

• Pendent.

• Technology transfer.

• Bangle.

• Earring.

• Plating services.

• Accessories.

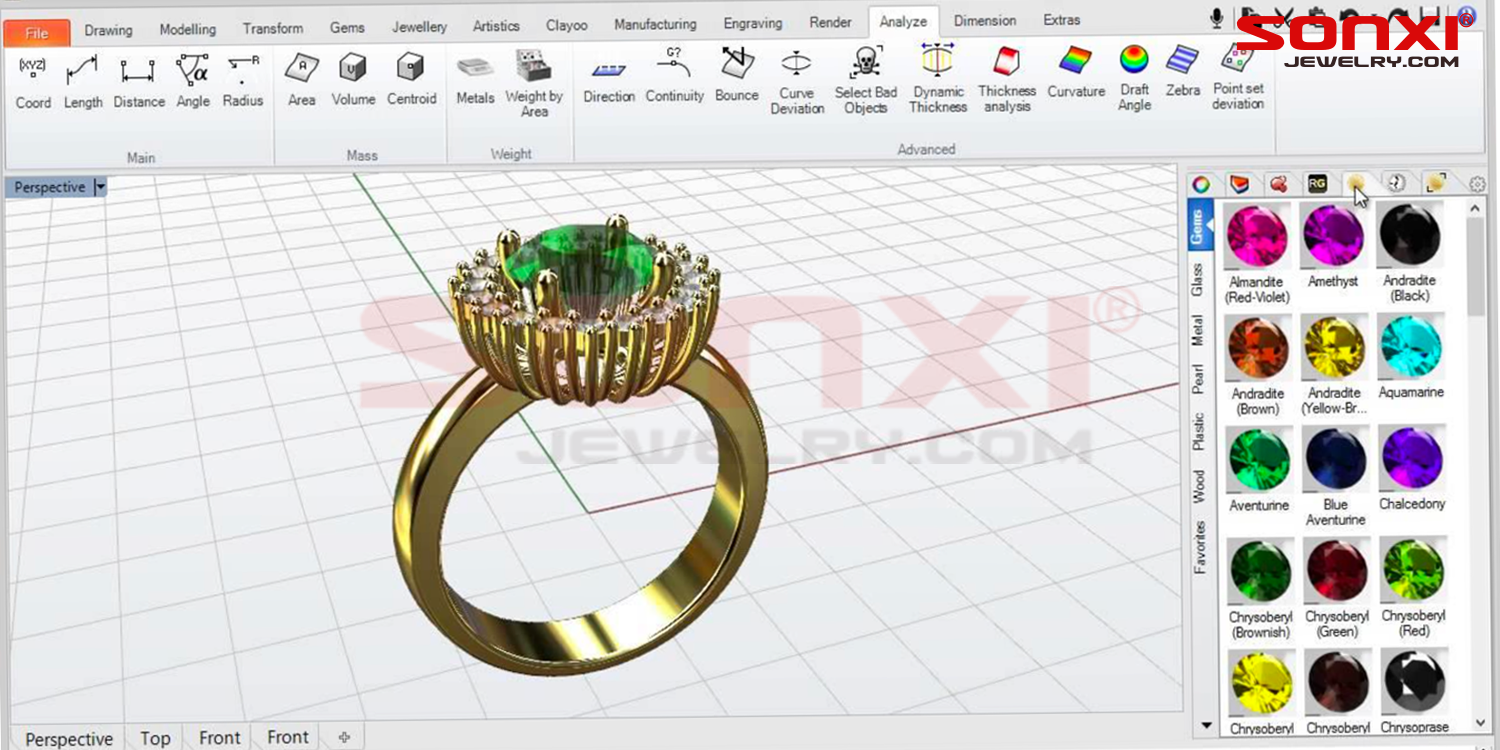

DESIGN AND MODELING

• 3D design with Rhino.

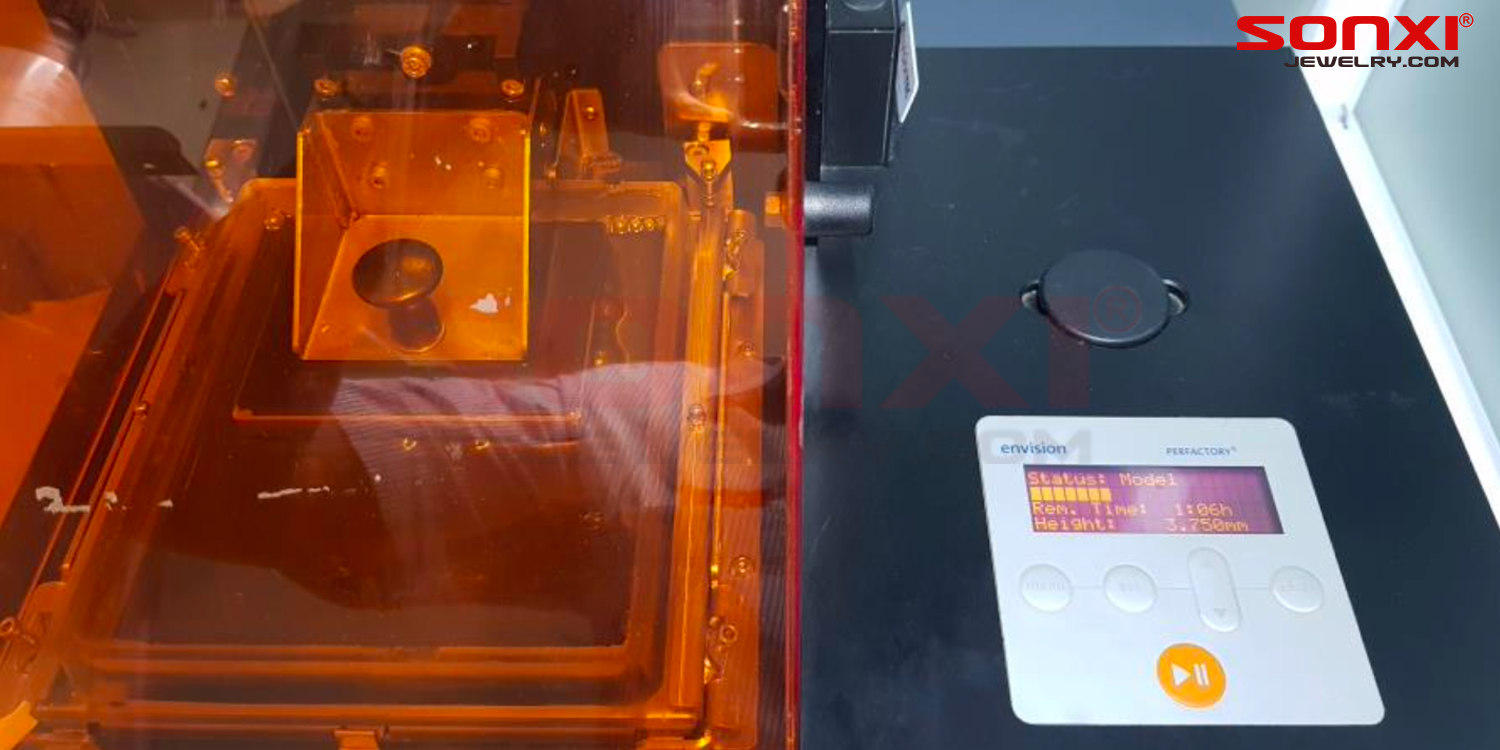

• 3D model printing with Aureus Envision TEC.

STONES AND GEMS SETTING

• Micro Setting.

• Channel Setting.

• Prong Setting.

• Pave Setting.

HANDICRAFT STONE SETTING

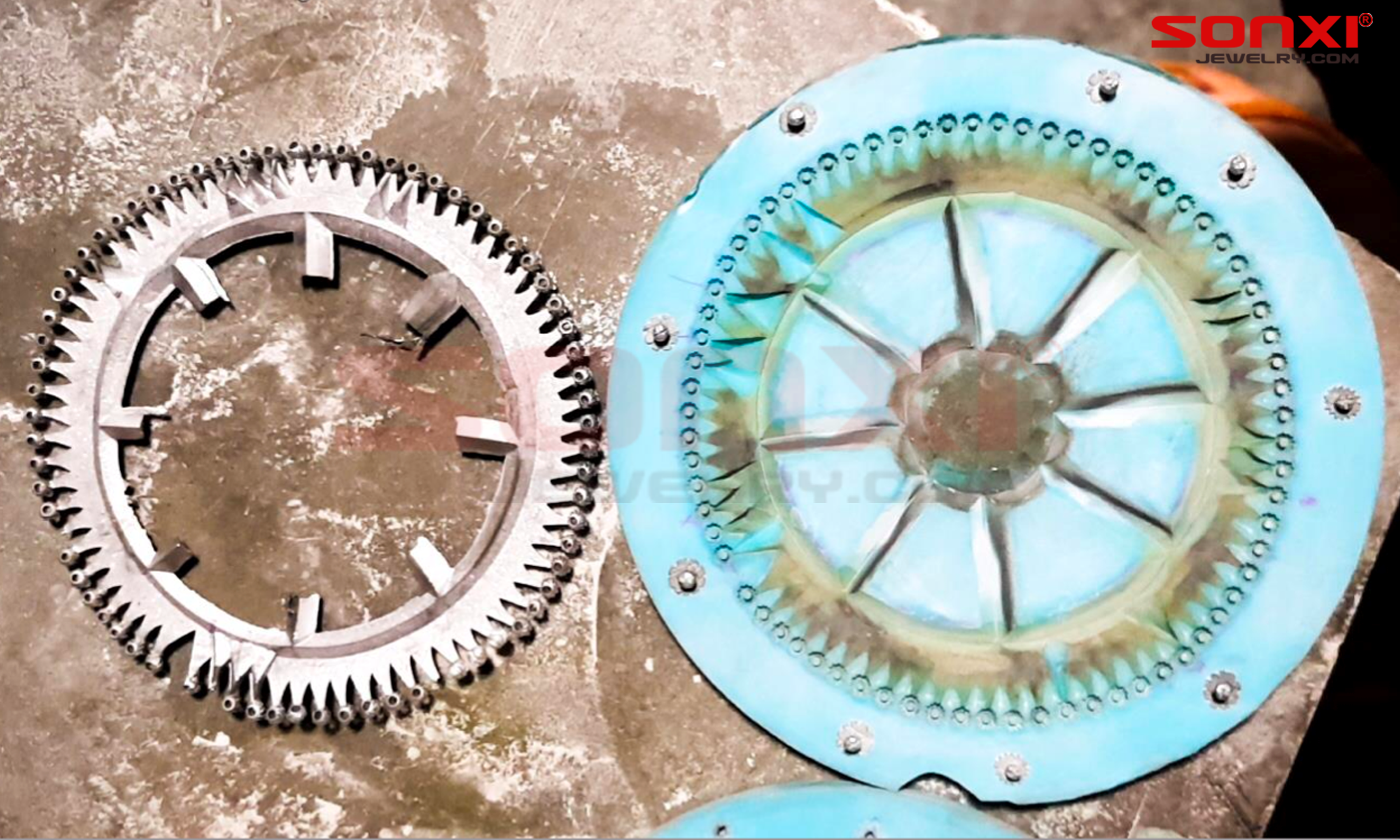

• Jewelry mold was made by injection machine Raceway. Then each piece of mold was stone setting by classic craftsmanship.

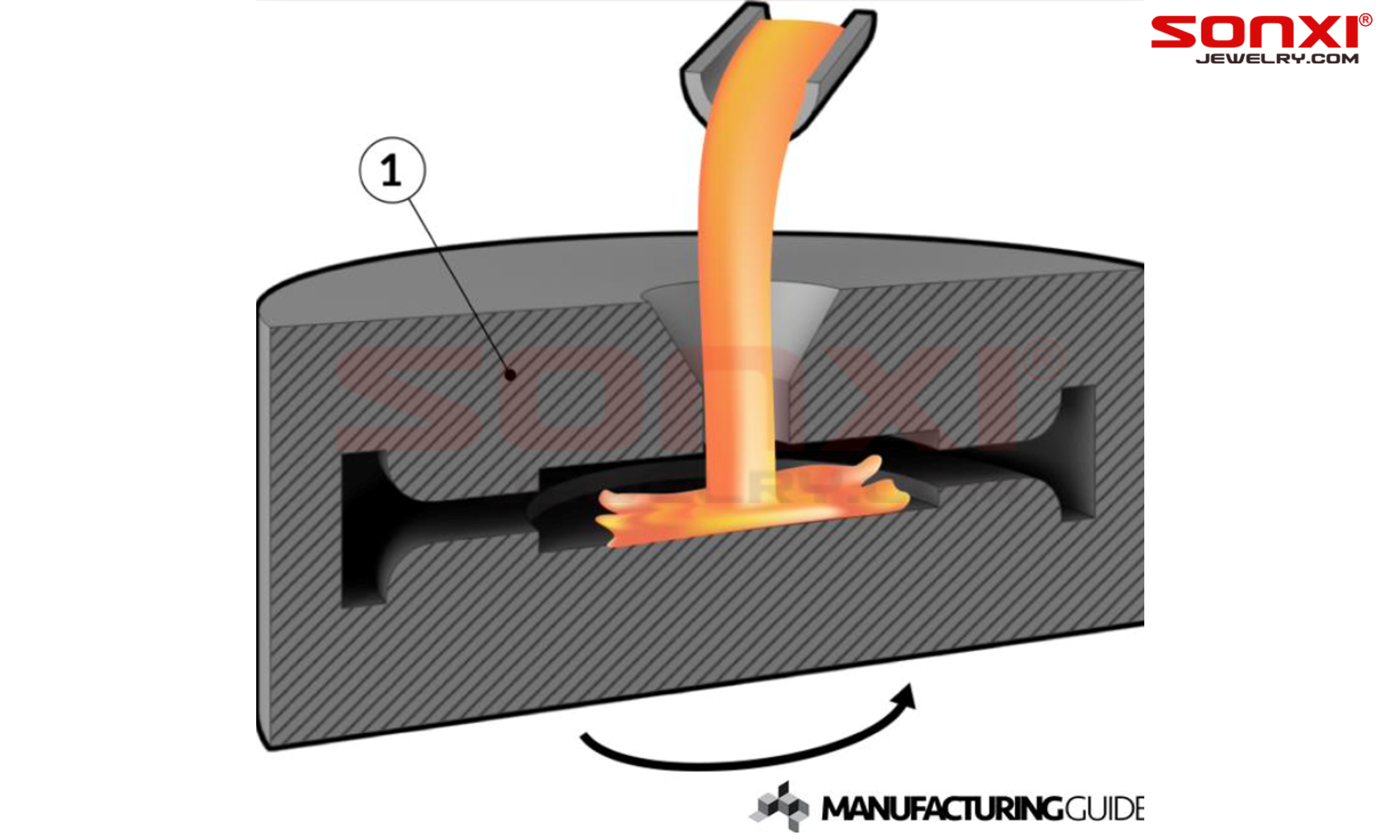

LOST WAX CASTING

• We place the wax piece in the metal can and enrobe it in fine paster. The canister then was placed in a furnace where the wax transforms into liquid and flowed away, leaving a negative space in plaster.

• Molten metal was poured through the ducts of plaster to fill the negative space.

SEMI-CENTRIFUGAL CASTING

• Semi centrifugal casting process is used only for symmetrically shaped objects and the axis of rotation of the mold is always vertical.

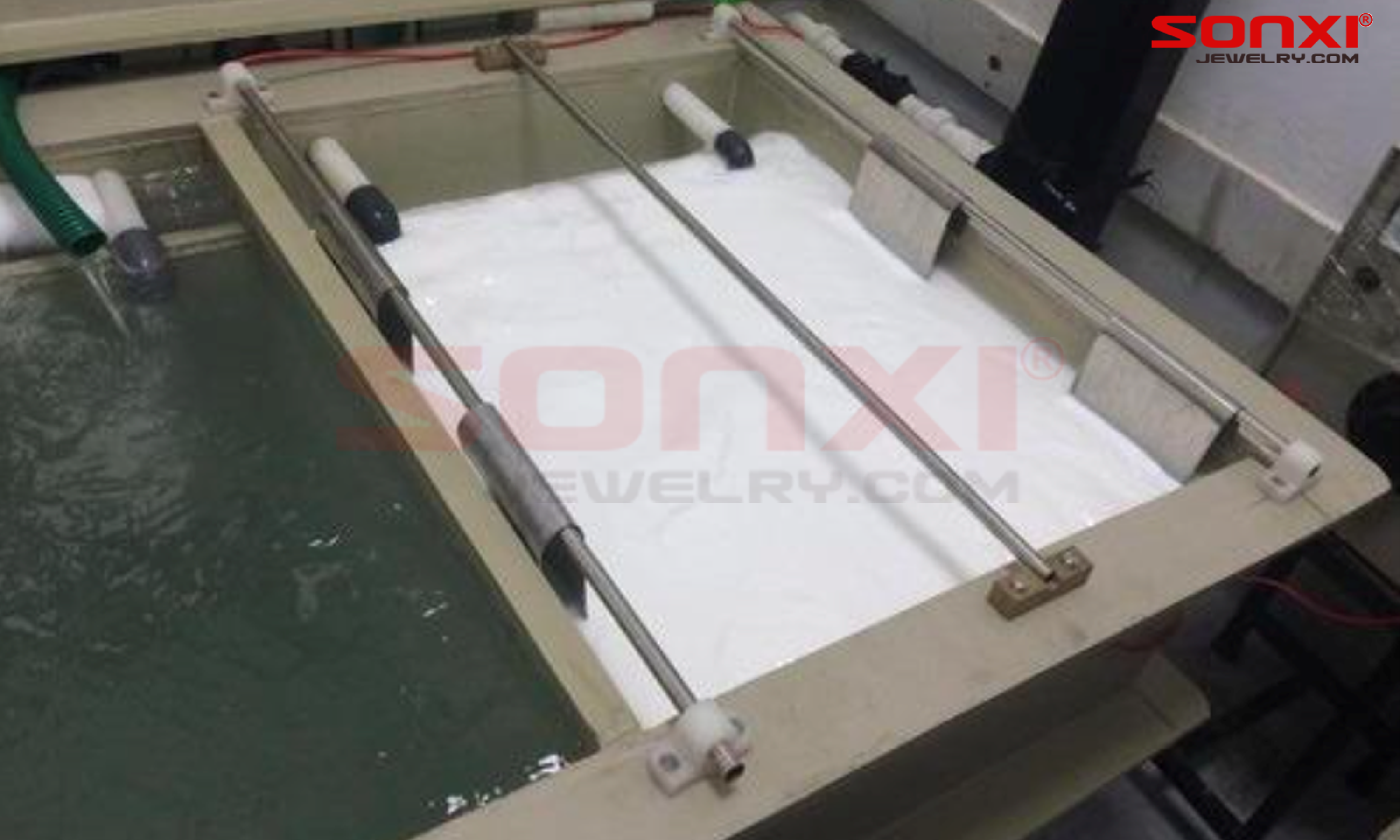

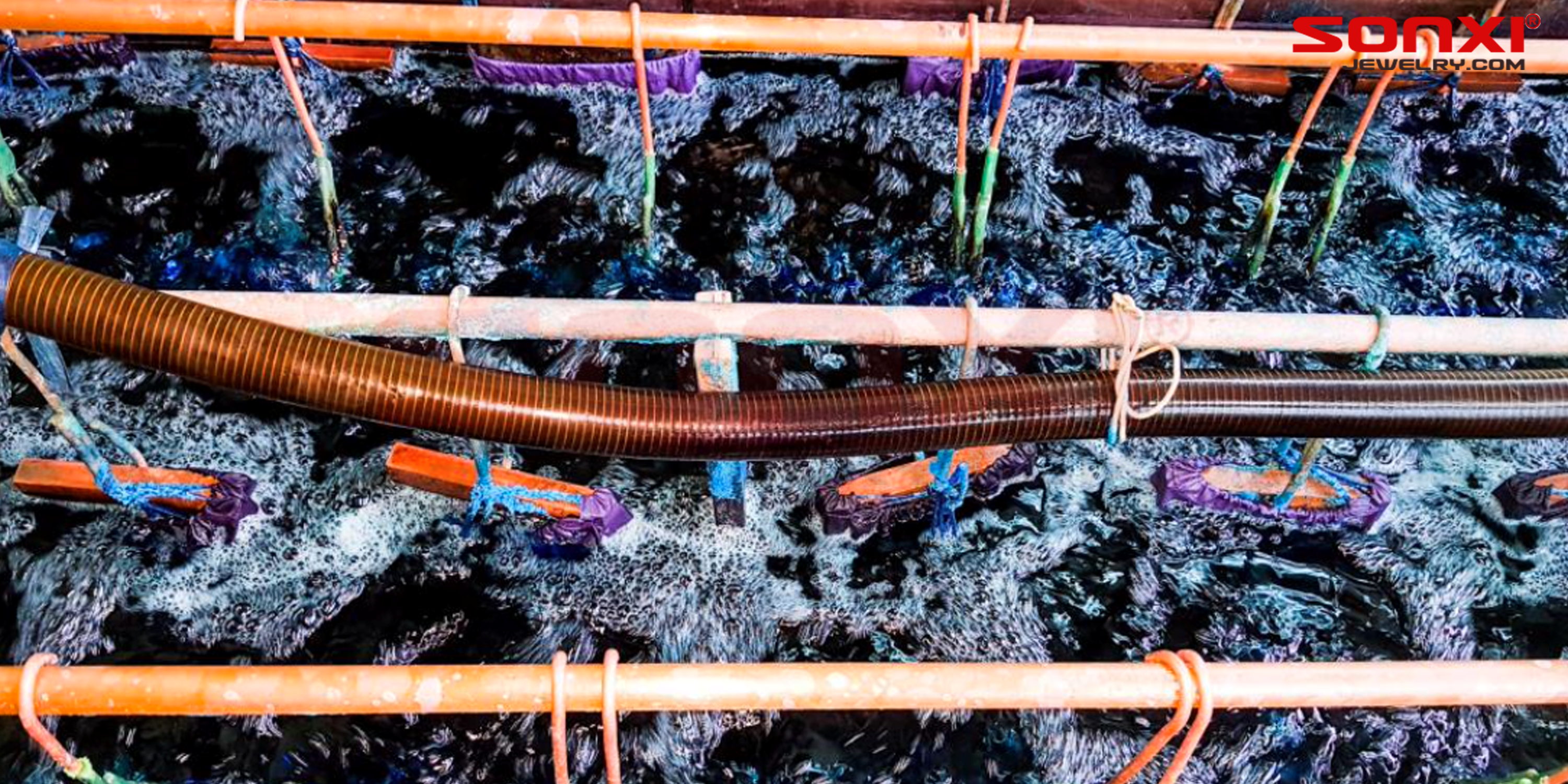

WET PLATING - FREE NIKEL

• 14K, 18K, 24K Gold Plating.

• Rose Gold Plating.

• Silver Plating.

• Ancient Silverstone.

• Electro-plating Technique.

• Matte Finishing.

• Rhodium Plating.

• Ancient Brass Tone.

• Jet Black Color.

• Electrophoretic Lacquer Coatings Technique.

ELECTRO-PLATING TECHNIQUE

• Nickel Free.

• Rose Gold Plating.

• Silver Plating.

• Matte Finishing.

• Ancient Brass Tone.

• Rhodium Plating.

• Jet Black Color.

• Ancient Silverstone.

PHYSICAL VAPOR DEPOSITION (PVD)

• Material: Aluminum, Titanium, Zirconium, Chromium, Silicone, Boron are used as targets. Under a variety of physical processes, ion metal combine with reactive gas ( Nitrogen, Oxygen, Acetylene, Methane, Argon) to create ceramic layers.

• Depending on the type of ceramic and the proportion of elements, we determine the color and mechanical properties of coating layers.

PVD COATING

• Under high vacuum conditions.

• Metals and Ceramics coating.

• High and low-temperature process.

• Suitable for metal, glass, plastic.

• Variety choice of colors.

• Food Grade Coating.

• Higher productivity.

• Green and clean process.

QUALITY CONTROL

• Color checking by CIELAB tester.

• Strength of stone and gemstone on mounting.

• Sending sample to Bureau Veritas for third party qualification if needed.

OUR ADVANTAGE

• Strong experience in Jewelry design.

• R&D department for Plating and PVD Coating.

• Unique combination Wet plating and PVD.

• Skillful production team: R&D, Craftsman, Casting, QC, Customer Relationship.

• Production capacity up to ~ 60.000 units each month.

• Invest in high - quality instruments & machines.

--- THANK YOU ---

EARRINGS

EARRINGS  MEN'S & WOMEN'S RINGS

MEN'S & WOMEN'S RINGS  BRACELETS & BANGLES

BRACELETS & BANGLES  ROUND XIMEN

ROUND XIMEN  LARGE BRACELETS

LARGE BRACELETS  JEWELRY SETS & PENDANT

JEWELRY SETS & PENDANT